Permafrost Engineering Problem along China-Russia Crude Oil Pipeline and Mitigative Measure

0 Comment(s)

0 Comment(s) Print

Print E-mail China.org.cn/Chinagate.cn by Li Guoyu,Cao Yapeng, April 11, 2022

E-mail China.org.cn/Chinagate.cn by Li Guoyu,Cao Yapeng, April 11, 2022

The China-Russia Crude Oil Pipeline (CRCOP) is one of the four key national energy strategic channels and the part in China will be constructed in two stages. The lines 1 and 2 were officially operated in January 2011 and January 2018, respectively, which import 30 million tons of Russian crude oil each year, taking on 58% of onshore crude oil imports of China. The CRCOP had transported nearly 200 million tons of crude oil by January 1, 2021, which played an important role in ensuring national energy security, diversifying oil supplies and transportation patterns, deepening Sino-Russian strategic cooperation, and promoting economic and social development. CRCOP, with a total length of 1 030 km, starts from the Skovorodino oil station of the Russian East Siberia-Pacific Oil Pipeline, enters China from the Xing’an Town of Mohe, extends along the eastern slope of the Greater Khingan Mountains from north to south, crosses the Nenjiang Plain and ends at Daqing Linyuan Petroleum Station (Figure 1). The pipe, made of L450 (X65) grade steel, has the outer diameter of 813 mm, wall thickness of 11.9 mm (12.5–17.5 mm in permafrost areas), and design pressure of 8 MPa (local 10 MPa). The traditional laying method of ditch burying with the depth of 1.6–2.0 m is employed in the permafrost areas and the Russian low-freezing-point crude oil is transported at normal temperature in a sealing manner. The pipeline in China has the total length of 953 km, including 441 km in the discontinuous permafrost area of Mohe-Gagdaqi section and 512 km in the deep seasonally frozen region (frost depth > 1.5 km) of the Jagdaqi-Daqing section. The section in the permafrost area includes 119 km in the warm and ice-rich permafrost and 50 km in the permafrost marshland region.

The construction of CRCOP faces three challenges: permafrost degradation, severely cold environment, and fragile ecology. This paper proposes innovative techniques and systematic solutions aiming at permafrost based on years of research experience in CRCOP, which ensures the safe operation, ecological restoration, and green construction of CRCOP, and provides reference for the construction, operation, and maintenance of similar projects.

Figure 1 Routing of China-Russia crude oil pipeline and distribution of permafrost and seasonally frozen ground near pipeline route

Permafrost problems along CRCOP

The permafrost engineering problems seriously threaten the construction and operation of CRCOP. The thawing of permafrost causes the instability of pipe foundation and the degradation of the surrounding environment. In addition, the pipeline is also affected by frost heaving, icing, and freeze-thaw landslide.

Climate warming accelerates the degradation of permafrost along the pipeline. Existing monitoring data show that the permafrost in Greater Khingan Mountains and Lesser Khingan Mountains has degraded by 35%–37% in the context of climate warming, compared with that in the 1970s. Degradation and thaw settlement directly affect the safe operation of CRCOP.

The permafrost problems in the construction and operation of CRCOP are complex, mainly manifested in the following four aspects.

(1) Severe permafrost and eco-environmental geological problems. The permafrost area along the pipeline is located near the southern boundary of the Eurasian permafrost area, which belongs to the ecosystem protection permafrost— hingan permafrost. Khingan permafrost has high temperature (−1.8 °C to −0.7 °C from south to north), rich ice (the ice content is 80%–90% near the upper limit of permafrost), discontinuous distribution (the distribution area of permafrost varies from 0–20% to 60%–70% from south to north), poor thermal stability, and high sensitivity to disturbances (such as engineering activities, reclamation, and fire) of the environments (such as dense vegetation and organic soil capping), which makes it difficult to protect permafrost. Besides, the pipeline passes through northern virgin forests and wetlands. Therefore, the degradation of permafrost may cause a series of eco-environmental geological problems, such as degradation of ecological services of forests and wetlands, soil erosion, environmental pollution, and ecosystem alienation and degradation. Therefore, attention should be attached to the environmental management and protection with consideration to the thermal disturbances in pipeline construction and operation.

(2) The permafrost degradation acceleration caused by heavy excavation. About half of U.S. Alyeska Crude Oil Pipeline is supported by thermosyphon cooled pile for overhead laying above ground, with small thermal disturbance to permafrost. The Canadian Norman Wells Crude Oil Pipeline with a small diameter (outer diameter of 323.9 mm) is buried in the ground, with low oil temperature. After the crude oil is transported 50 km from the inlet, the oil temperature, controlled by the surrounding soil temperature, is relatively stable. In the ice-rich permafrost along the Skovorodino-Mohe section of CRCOP, the pipe foundation is mainly built with frost heaving-insensitive soil (such as sand gravel) instead of frost heaving-sensitive fine-grained soil. Considering the natural and social environment conditions (e.g., fire prevention) along the pipeline, the section within China is buried in the ground. The pipeline passes through a large area of forest (coverage of 70%), wetlands and many villages and towns, and the heavy excavation (depth: 2.5–6 m, width: 2–3 m) exposes

permafrost and the pipe ditch accumulates water, which causes the melting of underground ice. Therefore, how to excavate pipe ditches and lay pipes reasonably is a major challenge to the eco-environment protection of permafrost, forests, and swamps along the pipeline.

(3) The permafrost thawing acceleration caused by high oil temperature. The pipeline, like an internal heat source which operates at positive temperature throughout the year, continuously releases heat to the permafrost layer around the pipe (monitored oil temperature in 2018 is 12.6 °C–24.6 °C). Compared with that of the aboveground permafrost engineering, the thermal disturbance of buried pipeline with high oil temperature is direct and severe. Therefore, the permafrost at the bottom of the pipe has a greater thawing depth (nearly 10 m in 2018), which increases the risk of thaw settlement and the damage to the environment.

(4) The hydrogeological, engineering geological, and environmental geological problems. The area along the pipeline features severely low temperature (the lowest temperature in Mohe reaches −52.3 °C) and large snowfall (the annual mean snowfall in Mohe is 35 cm) in winter while high temperature (the highest temperature in Mohe can reach 35.2 °C) and large rainfall (the annual mean rainfall in Mohe is 500 mm) in summer. The high underground water level, abundant surface water and underground water, extensive swamps, dense forests, frequent transitions between permafrost and thawing areas, and wide distribution of freezing-thawing sensitive soils (shallow fine-grained soil and peat soil) pose high risks of frost heaving and thaw settlement.

2Principles of protecting the permafrost foundation

The typical stratigraphical layers along the CRCOP are peat soil (thickness: 0.8–0.9 m), fine-grained soil (thickness: 0.9–1.9 m), gravel soil (thickness: 1.8–4.7 m), and strong (weak) weathering bedrock from top to bottom[14]. The layers below the pipeline are mostly gravel sand and bedrock with small thaw-settlement coefficient and good engineering geological conditions. At the same time, the pipe can withstand large differential thawing-settlement deformation attributed to the good flexibility of the steel. According to related studies, the largest differential thawing-settlement deformation of the pipe under certain conditions can reach 565 mm[15]. Therefore, in order to reduce the cost of construction and operation, we propose the principles of thaw control for the regulation of permafrost temperature, which is different from the cooling regulation principle adopted by the Qinghai-Tibet Railway, the Qinghai-Tibet Highway and the U.S. Alyeska Crude Oil Pipeline projects. The principles of thaw control aim to control the deformation of the pipe within moderate range to ensure the safe operation of CRCOP.

Based on the principles of thaw control, a variety of new measures for the prevention and control of permafrost thawing have been developed. The on-site demonstration projects, indoor physical model tests, and numerical simulation tests have been conducted, which verify the engineering effects and optimize the design parameters. Combined with traditional permafrost treatment technology, a set of prevention and control countermeasures for the permafrost thaw settlement of CRCOP are formed. At the same time, a complete water-heat-deformation long-term monitoring system has been established to provide real-time monitoring data and ensure the safe and stable operation of CRCOP.

3Prevention and control countermeasures for the permafrost disasters of CRCOP

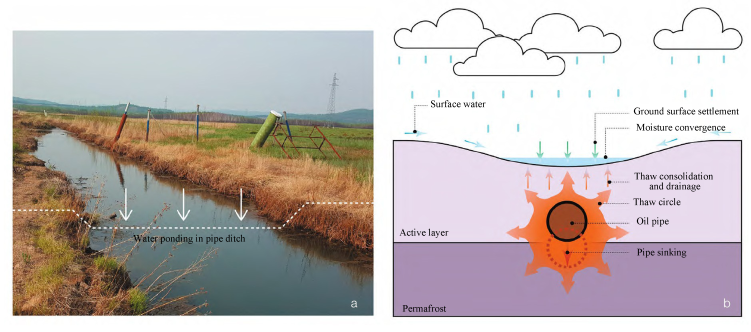

At present, the most serious disaster faced by CRCOP is thaw settlement (Figure 2). This paper mainly elaborates

Figure 2 Thaw settlement along China-Russia Crude Oil Pipeline

(a) Water ponding in the right-of-way (ROW) along China-Russia Crude Oil Pipeline; (b) Schematic diagram of evolution mechanisms of thaw bulb and pipeline settlement

the prevention and control of thaw settlement as well as the protection of the permafrost environment. Considering the climatic and geological conditions, eco-environment, hydrological system, economic benefits, and practical efficiency, efforts should be made to control the permafrost environment and oil temperature within the scope of the pipeline, develop new cooling and heat-dissipation devices, and improve the bearing capacity of the pipe base as well as the strength and flexibility of the pipe material. A complete set of countermeasures for the prevention and control of permafrost disasters should be formulated to ensure the safe operation of CRCOP. The specific measures are shown in the following four aspects.

Increasing the pipeline wall thickness

Increasing the pipeline wall thickness can directly improve the strength, flexibility, and resistance of the pipeline to deformation and damage. In non-permafrost regions, the wall thickness of CRCOP is 11.9 mm. However, in permafrost regions, according to different ice content and sensitivity to thaw settlement, the wall thickness is increased to 12.5–17.5 mm, which significantly improves the resistance of the pipeline to frost heave and deformation. This measure has been widely applied throughout the permafrost regions.

Controlling the oil temperature

High oil temperature is the direct cause of permafrost thawing. Regulating the inlet oil temperature to approach the soil temperature around the pipeline can reduce the heat transfer from the pipeline to the permafrost, thereby reducing the permafrost thawing. For example, the inlet oil temperature of the Canadian Norman Wells Crude Oil Pipeline is cooled to −1 °C for transport, which significantly reduces the pipe–soil heat transfer[16] and controls the thaw settlement to some extent. In the summer of 2018, the oil temperature near the first station (Khingan Town) of Mohe of the CRCOP within China reached a maximum of 24.6 °C. Therefore, it is necessary to take measures such as cooling the crude oil at the inlet of the pipeline or crossing the low-temperature river to reduce the inlet oil temperature to mitigate the thawing of permafrost.

hanging the soil at the pipe base

Frost heaving-sensitive soil and thawing unstable permafrost are widely distributed in the shallow ground along the CRCOP, such as clayey silty sand and peat soil with high content of fine particles. When such permafrost has rich ice, the thawing and refreezing will cause greater deformation, posing a safety risk to the pipeline. The CRCOP changes its soil at the pipe base with the frost

heaving-insensitive soil to improve the bearing capacity and reduce the thawing-settlement deformation. This measure has been widely applied throughout the permafrost regions.

Regulating the permafrost temperature

Restoration of surface vegetation. After laying the pipeline, the restoration of surface vegetation (multiple cropping) within the pipeline ditch can change the water and heat transfer conditions of the ground-air interface, reduce the surface heat absorption, and lower the surface temperature. For example, the average surface temperature of swamp meadow is 2.4 °C lower than that of sparse turf. With the decrease in surface temperature, the thawing of permafrost and the differential thawing-settlement deformation of pipeline are significantly mitigated. At the same time, vegetation restoration can comprehensively improve the eco-environment affected by pipeline construction.

Heat pipe, a closed gas-liquid two-phase flow circulation heat transfer device. In the cold season, the cold flow in the nature can be transferred to the permafrost to reduce the temperature. In the warm season, when the temperature difference between the condensation section and the evaporation section of the heat pipe fails to reach the start-up temperature, the heat pipe stops working, and only a small amount of heat is transferred to the ground through heat conduction. In a whole year, the thermal budget of permafrost is negative to cool, which protects permafrost from thawing. Heat pipe features simple construction and good cooling effect is thus widely used in pipeline construction and later maintenance. In the cold season of 2019, the monitoring data of a certain field showed that the ground temperature at the depth of 4 m and 3 m of the protected segment of heat pipe was 1 °C and 2.5 °C lower than that of the unprotected section, respectively. At present, more than 12 000 heat pipes have been employed in ice-rich, ice-saturated, and soil-bearing ice zones along CRCOP.

Longitudinal air-ventilated pipe, an air-ventilated and heat transfer system buried in parallel on both sides of the oil pipe (Figure3). When the temperature of the soil around the oil pipe is higher than the air temperature in the air-ventilated pipe, the natural convection heat transfer occurs in the air-ventilated pipe, which releases the heat emitted by the oil pipe to the atmosphere. At the same time, cold air is brought into the ground to reduce the temperature of the soil around the oil pipe. When the temperature of the soil around the oil pipe is lower than the air temperature in the air-ventilated pipe, the air-ventilated pipe stops working like a heat pipe. When the wind speed in the cold season is high, the air-ventilated pipe can also bring the cold flow in the atmosphere into the ground through forced convection to slow the thawing of permafrost. In addition, the thermal insulation layer at the bottom of the oil pipe can reduce the transfer of heat from the oil pipe to the permafrost bottom and slow the thawing of permafrost. The numerical simulation experiments show that the depth of permafrost thawing can be reduced by about 4 m after 20-year operation of longitudinal air-ventilated pipe. The device is suitable for some ice-rich, ice-saturated, and soil- bearing ice areas andpermafrost ecological protection areas.

Figure 3 Schematic diagram of longitudinal air-ventilated pipe

Horizontal U-shaped air-ventilated pipe. Horizontal U-shaped air-ventilated pipe, with the cooling principle similar to that of longitudinal air-ventilated pipe, is suitable for cooling a certain point or a small range of pipes, with the structure shown in Figure 4. The application of a U-shaped air-ventilated pipe with an outer diameter of 21.9 cm in a permafrost wetland area of CRCOP demonstrates a good cooling effect in the cold season, and the ground temperature 4 m below the ground surface near the air-ventilated pipe in the cold season is about 0.5 °C lower than that in the area without air-ventilated pipe. This measure is suitable for ice-rich, ice-saturated, and soil-bearing icy areas along the pipeline.

Figure 4 Schematic diagram of horizontal U-shaped air-ventilated pipe

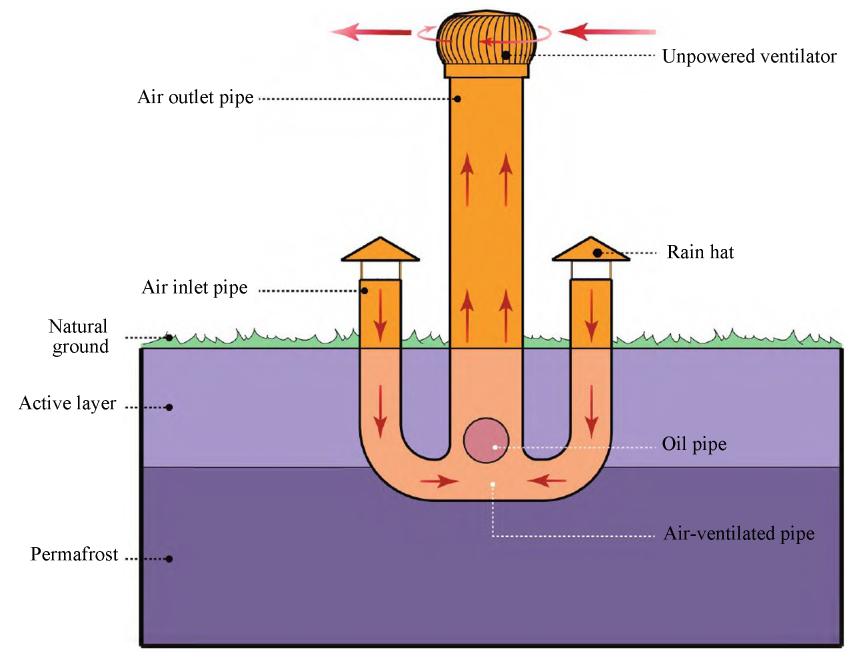

Horizontal W-shaped air-ventilated pipe, a device that uses heat convection exchange and ventilator to transfer heat, mainly composed of left and right air inlet pipes, central air-exhausting pipe, and unpowered ventilator (Figure 5). When there is no wind in the cold season, the temperature of the oil pipe is higher than the air temperature in the central air-exhausting pipe, and the air in the air-exhausting pipe floats up because of the heating of the oil pipe, leading to natural convection to transfer heat. Then, the unpowered ventilator is driven to suck the air in the air-ventilated pipe and accelerate the convective heat transfer. When there is wind in the cold season, the natural wind field drives the unpowered ventilator to suck the air in the air-exhausting pipe, which accelerates the air flow in the pipe to quickly release the heat emitted by the pipe to the atmosphere. At the same time, the cold flow in the atmosphere is transferred to the soil around the pipeline to slow down the thawing of permafrost. Because the wind is slower and the temperature is higher in the warm season, the W-type air-ventilated pipe, like the U-type air-ventilated pipe, stops working. The results of a large-scale indoor model test show that after 6 freeze-thaw cycles, the temperature 25 cm below the oil pipeline without and with W-shaped air-ventilated pipe is about 2.4 °C and 0.4 °C, respectively, which proves the cooling effect of W-shaped air-ventilated pipe. This measure is applicable to ice-saturated and ice-bearing areas along the pipeline.

Figure 5 Schematic diagram of horizontal W-shaped air-ventilated pipe

Thermal insulation of pipeline. An economical, reasonable and effective measure can directly and significantly reduce the heat transfer between the pipeline and permafrost and slow down the thawing of permafrost. In the permafrost section along CRCOP, almost the outer wall of the pipeline is all coated with 8 cm thick thermal insulation material (hard polyurethane foam). This measure significantly reduces the thawing range and rate of permafrost. Numerical simulation experiments have shown that the permafrost around the pipeline with 8 cm thick thermal insulation material thaw at half the depth of the pipeline without thermal insulation material in 50 years, which indicates that the thermal insulation has an obvious thermal insulation effect. In the sections with ice-saturated and soil-bearing ice layers, the combinations of thermal insulation with other measures, such as thermal insulation + soil replacement, thermal insulation + increasing wall thickness, thermal insulation + heat pipe, thermal insulation + U-shaped air-ventilated pipe, and thermal insulation + soil replacement + increasing wall thickness, have better prevention and control effect on permafrost thawing.

Air-ventilated and energy storage system, a device combining air-ventilated pipe heat dissipation with cold latent heat storage system based on phase change (Figure 6). This system can control thaw settlement and avoid frost heave and is mainly composed of left and right convection heat transfer channels, refrigeration box, and energy storage body. The heat transfer mechanism of this device is similar to that of air-ventilated pipe in the cold season. When the temperature is lowered in the cold season, the temperature of the energy storage body is lower than the phase change temperature, and the body undergoes a phase change and releases heat to prevent the box temperature from decreasing, thereby regulating the temperature of the permafrost around the pipeline to be too low to cause frost heave. In the warm season, the air-ventilated pipe stops working, and only a small amount of heat enters the underground refrigeration box and the permafrost through heat conduction to increase the temperature slowly. If more heat enters the system and the temperature of the energy storage system is higher than or close to the temperature of phase change, the energy storage system first undergoes a phase change and absorbs heat to slow down the thawing of the permafrost at the bottom of the box. Numerical simulation experiments have found that the air-ventilated and energy storage system has a good effect of controlling the thawing of permafrost, and the actual engineering effect is currently being verified on the spot. This measure is suitable for the prevention and control of the thawing of the ice-rich, ice-saturated, and soil-bearing icy sections along the pipeline.

Figure 6 Schematic diagram of air-ventilated and energy storage system

Air convective pipe embankment, an aboveground pipeline laying structure (Figure 7). This structure can avoid pipe trench excavation and permafrost disturbance as well as the impact of forest fire on the pipeline. The pipeline is laid in the non-sensitive coarse grain soil layer with frost heave and thaw settlement at the upper part of the crushed-rock layer to avoid the seasonal frost heave and thaw settlement. The crushed-rock layer can dissipate the heat from the pipeline and reduce the temperature of the soil at the bottom of the pipe embankment. Large indoor model test shows that after 6 freeze-thaw cycles, the maximum thawing depth of permafrost at the bottom of the air convective pipe embankment is only 17% of that of the traditionally buried pipeline, indicating that this measure has a good effect on controlling the thawing of permafrost below the pipeline. This measure is applicable to the ice-rich, ice-saturated, soil-bearing icy areas including permafrost wetlands along the pipeline.

Figure 7 Schematic diagram of air convective pipeline embankment

Prospects

Based on years of research and experience, this paper puts forward the principles of thaw control and a set of measures for mitigating and controlling the thaw of permafrost along CRCOP, which ensures the safe operation and green construction of CRCOP. However, the prevention and control of the permafrost disasters and the protection of the permafrost environment of CRCOP still need to be improved, and attention should be paid to the following four aspects in the future.

Improving the long-term monitoring system for the permafrost disasters along the pipeline. Supplying monitoring equipment and factors in key permafrost disaster areas and repairing the disabled monitoring system can ensure the continuous and complete acquisition of data along the pipeline. It is suggested to improve the pipe stress and strain measurement as well as the water, heat, force, and deformation monitoring for permafrost and pipe.

Developing new prevention and control measures for freeze-thaw secondary disasters. On the basis of research, development, optimization, and promotion of prevention and control techniques of thaw settlement of the permafrost, those for secondary and frost disasters (such as frost heave, icing, and river ice) should be strengthened to form a freeze-thaw disaster prevention and control system covering the entire pipeline.

Paying attention to the engineering and environmental problems caused by the continuous increase in oil temperature. The oil temperature in Russia is rising, far exceeding the designed temperature. It is essential to study the influence of high oil temperature on pipeline safety and the permafrost environment and then develop the corresponding prevention and control countermeasures.

Multi-factor systematic study on pipeline corridor. The CRCOP route overlaps the Greater Khingan Mountains Engineering Corridor, along which are distributed other engineers such as the Jagdaqi-Mohe Highway and Railway. In the context of climate change and environmental changes, the thermal state of the permafrost and the thermal stability of engineering corridor are affected by multiple factors. Therefore, the focus should be put on the systematic study integrating climate change, engineering corridor, permafrost, and environment in the future.

Author

Li Guoyu, Professor of Northwest Institute of Eco-Environment and Resources, Chinese Academy of Sciences (CAS).

Cao Yapeng, corresponding author, PhD candidate at the Northwest Institute of Eco-Environment and Resources, Chinese Academy of Sciences (CAS).

Citation: Li Guoyu, Cao Yapeng, Ma Wei, Jin Xiaoying, Chen Pengchao, Yu Qihao, Zhang Zhongqiong, Mu Yanhu, Jin Huijun.

This article is contributed by Bulletin of Chinese Academy of Sciences.